Last week in the office we talked a lot about the new meaning of the term “3D architecture” that appeared lately. Not long ago the only possible meaning of 3D was, apparently, “render”, but now with growing popularity and also accessibility of 3D-printing the situation is changing. You would ask then why we talked about it last week? Because we all were enthusiastic about the ViewConference, where Luca Deriu together with Massimo Temporelli spoke last Tuesday about the way from 3D-renders to 3D-printing and the new opportunities that appear now. Have you seen in the news lately that one of the American supermarkets is now offering its customers 3D-printing service as in the 90-s we were printing our vacation photos? What will come next? What it is for us, designers and architects, – a way for making nicer and faster prototypes for concept presentation or a new tool for building the project full scale? Hereby we would like to invite you into this discussion by publishing our exclusive interview with Martine De Wit from DUS Architects (Amsterdam) who is now working on a major 3D architecture project – literally 3D-printing a house.

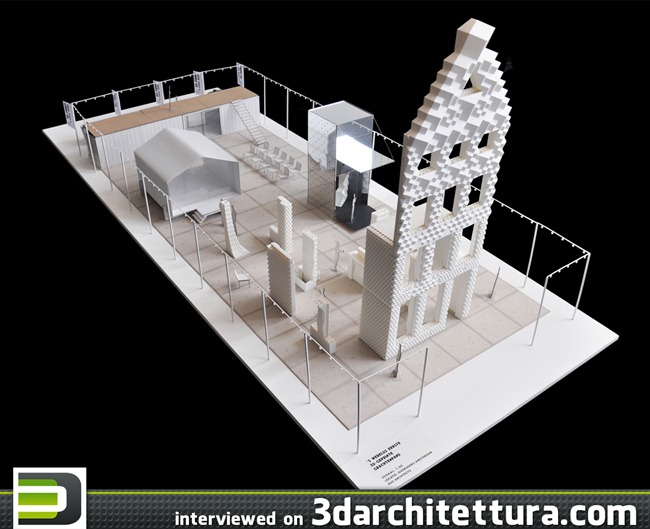

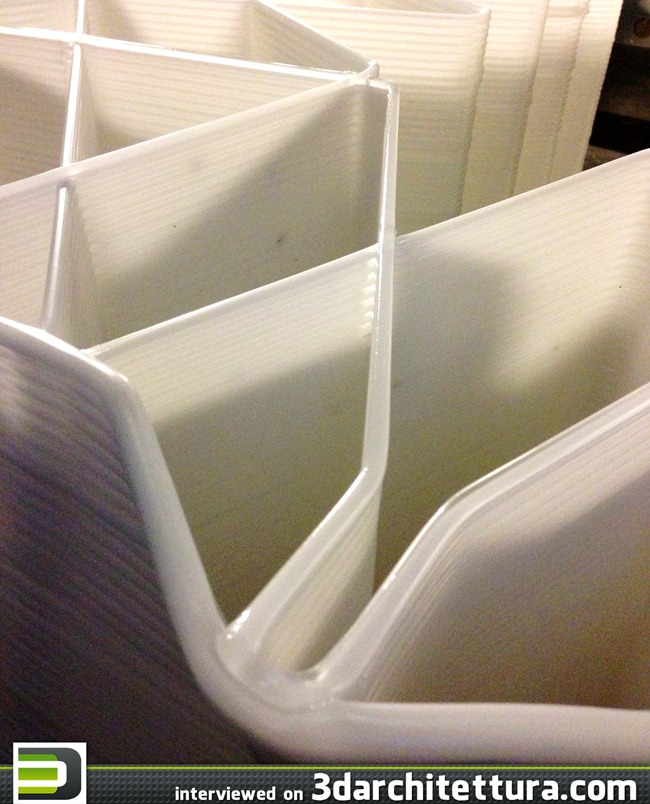

The project of the world’s first 3D-printed house is a unique technical and architectural experience happening publicly. The Northern Canal Belt project is supposed to revitalize some unused canals in North Amsterdam. The first 3D-printed house will have a shape of a traditional Dutch canal house to support local identity, at the moment this project involves different construction and research companies and authorities. Experiments include developing of the material, a particular sort of PLA bioplastics polypropylene, and work on the construction details based upon the 3d-printed model in the scale of 1:20 and than full size. DUS architects have developed first 6 meter high 3D printer that prints with different types of (bio) plastics, and in the near future also with recycled plastic. This way, building parts of houses and even entire rooms can be printed in one piece. Also unique molds for facades and furniture can be created. The house will be printed layer by layer, room by room, starting from the front facade and the first welcoming room of 30 sq.m. that would come as one element. Within the 3D printed walls are spares for connecting construction, cables, pipes, communication technique wiring.

You can learn more and follow this project more closely at www.kamermaker.com and now read an exclusive blitz-interview of Martine de Wit, DUS architects, Amsterdam for 3darchitettura.

3dA: How you have started work with 3d-printing?

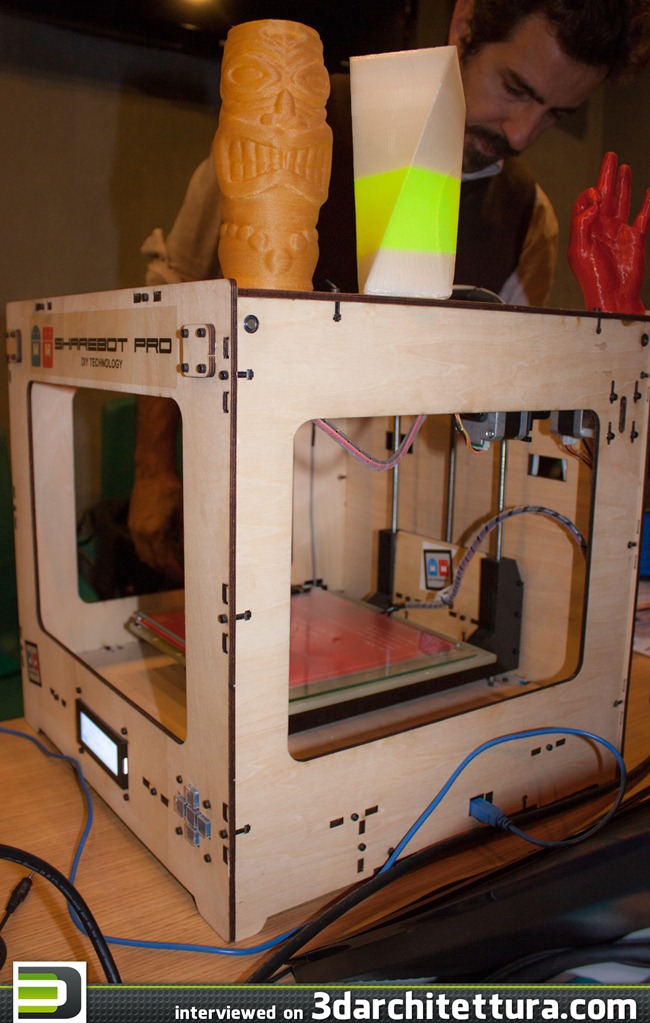

Martine de Wit: We have several Ultimakers (self build 3D printers) in the office for printing models. Since 5 years use 3D printing techniques for our model making.

3dA: How many people are involved in your team?

MdW: The printing team at the moment consists of 4 full-time people. Together we work on designing, drawing, programming, printing and organizing everything.

3dA: Your 3d-printer for this project was custom-made, then why you decided not to print the building as a whole, but to build it from the printed details? What is then the difference from the usual construction process?

MdW: To build a printer as big as a building is to first build a building before building the building. To us that sounds not very smart. Already we question ourselves if the printer maybe might to big: Most parts we print are smaller. The difference with traditional building is the following: we are printing the building parts. And yes we are searching for ways to integrate 3D printing in the traditional way of building.

3dA: What kind of plastic you use? And what about the ecological concerns associated with the plastic building?

MdW: We are developing a plastic together with our material partner. Is this ok for the environment? I would state it’s not more environmentally unfriendly then to build a house in any other material. But maybe even more friendlier (less transport, less spoiling of resources, better recycle possibilities, better possibilities to use recycled materials).

3dA: Can the printed building really be used for living or for work? How you solve the problems of heating etc?

MdW: We aim to build the building in a way it’s suitable for working and living. How to solve problems: we don’t know yet. Most of them, like heating will be just traditional like every building is heated.

3dA: What you think about the estimated costs for 3d-printed buildings compared to the tradition construction? Can it become a serial production?

MdW: It can become cheaper. Like all other inventions thinking of cars, computers, mobile phones etc. At first very expensive, and maybe not so useful, but in the end available for (and needed by) everybody. But the nice thing about 3D printing is that every object can be unique: so it won’t be a mass production as we know from the past.

3dA: What are the main difficulties that you faced in this project?

MdW: At the moment we are working on finding the right material and to see how we can print faster.

3dA: Now 3d-printing is a very popular subject, do you think it’s just a trend of the moment, a “new toy”?

MdW: No, this is the newest industrial revolution.

3dA: Which perspectives can this technology have in the future?

MdW: Printing houses.

3dA: We already can’t imagine design and architecture without 3d-renders – will 3d printing substitute 3d renders?

MdW: No. This is something totally different.

Credits: DUS architects in collaboration with Ultimaker, Fiction Factory, Joris van Tubergen and Xtrution.

Funded by Stichting DOEN and Netherlands Architecture Fund.

Photo credits: DUS architects

ViewConference photos by PlaySys

Text by Elena Kartseva